|

| April 28, 2020 | Volume 16 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Laser-created patterns on aircraft wings can provide a fast, eco-friendly way of de-icing

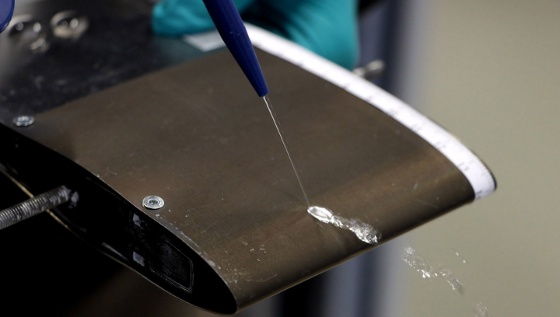

This NACA airfoil has been treated with a water-repellent laser-patterned surface. [Photo: © Airbus]

Ice formation presents a safety risk for aircraft. A thin layer of frost settling on the wings or other critical points such as the tail can adversely affect the aircraft's aerodynamics. Lift may decrease and drag may increase. Ice accumulating on probes and sensors can compromise air speed measurements that are critical to in-flight safety.

On the ground, the de-icing task falls to special vehicles that spray chemical agents onto all vulnerable surfaces. However, fluids of this type are harmful to the environment and expensive. Moreover, a substantial amount -- 400 to 600 liters -- is needed to de-ice a plane.

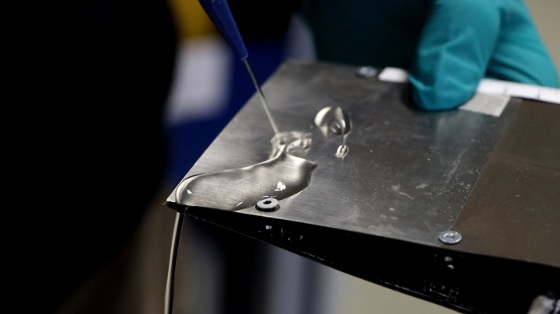

A comparison showed that water adheres to the unstructured (untreated) NACA airfoil and freezes within seconds at sub-zero temperatures. [Photo: © Airbus]

Airborne aircraft also have to be protected against this frosty peril. In most cases, ice protection systems such as heating elements are used on board to do the job. The great drawback of these heaters is that they increase fuel consumption.

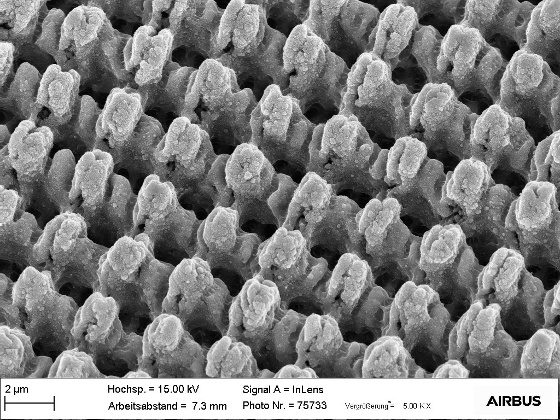

Using a technology known as Direct Laser Interference Patterning (DLIP), a research team at Fraunhofer Institute for Material and Beam Technology IWS (Dresden, Germany) collaborated closely with project partners Airbus and TU Dresden to develop a process that allows complex, meandering surface structures to be created at the micron and submicron scale of airplane surfaces to decrease ice accumulation and accelerate de-icing. What sets this process apart is that the researchers combined DLIP with ultra-short-pulse lasers to create multilevel, 3D microstructures on wing profiles in a single step.

As a result, some of the ice simply loses its grip, depending on the conditions under which it froze, and spontaneously detaches after reaching a certain thickness. If heaters need to be used to quicken the process, de-icing requires 20 percent less heating energy when applied to the DLIP-treated surface.

Other advantages of the new process are that it potentially reduces the required amount of environmentally harmful de-icing agents and the time passengers spend waiting for the plane to be de-iced. Savings also apply to in-flight power and fuel consumption. The process, once applied, can even reduce the aircraft's weight if smaller heating units are installed. The combination of these effects has yet to be achieved using conventional technologies.

A close-up shot of the NACA airfoil's surface taken from above. It was created using the laser-patterning DLIP technology. [Photo: © Airbus]

This DLIP process was developed in a concerted effort between Fraunhofer IWS and TU Dresden in order to find the optimized DLIP surface structure. The IWS experts developed the patterning process to transfer the optimized structure onto a final demonstrator -- a complex three-dimensional National Advisory Committee for Aeronautics (NACA) airfoil that served as a miniaturized but realistic wing model. The NACA airfoil was then tested by Airbus experts in a wind tunnel. The performance tests were carried out with a structured (treated) NACA airfoil and an unstructured (untreated) NACA airfoil serving as a reference under realistic conditions at wind speeds ranging from 65 to 120 m/s, with air temperatures below -10 C and at various humidity levels.

The partners from Airbus were able to demonstrate that ice growth on the functionalized surface is self-limiting. In fact, the ice falls off after a certain amount of time without requiring added surface heating.

Additional experiments also showed that it took 70 seconds for the ice on an unstructured (untreated) airfoil to melt at 60 W of applied heat. The ice on the structured (treated) airfoil receded completely after just five seconds with the same amount of applied heat.

The DLIP technology accelerated the process by more than 90 percent. It took 75 W, or 25 percent more heating power compared to the DLIP surface, to remove the ice on the unstructured demonstrator.

"In this wonderful collaboration with Airbus, we demonstrated for the first time and in a realistic way the great anti-icing potential that can be tapped with large-scale laser surface patterning. With our DLIP approach, we realized biomimetic surface structures on a complex component like the NACA airfoil, and demonstrated its distinct advantages over other laser processes," said Dr. Tim Kunze, team leader for Surface Functionalization at Fraunhofer IWS.

VIDEO: Interview with Elmar Bonaccurso and Vittorio Vercillo, material scientists at Airbus, and Tim Kunze and Sabri Alamri, scientists at Fraunhofer IWS.

His colleague, Sabri Alamri, added, "The application of micro- and nanostructures on metal prevents water droplets from adhering. Inspired from nature, this is widely known as the 'lotus effect.' With our new DLIP process, we can create a fragmented surface to significantly reduce the number of adhesion points for ice. We will soon publish a paper on the results."

Project partner Elmar Bonaccurso, research engineer for Surface Technology/Advanced Materials at Airbus, added, "Ice formation is particularly dangerous during landing. Water on the surface freezes within milliseconds when the aircraft flies through the clouds at sub-zero temperatures. This can disrupt the functions of control elements such as landing flaps and slats, which impairs the aerodynamics. Today, we use hot air sourced from the engines to heat wing surfaces. The water-repellent structure, which we developed with our partner Fraunhofer IWS in the EU project Laser4Fun, is an attempt to replace conventional technologies with eco-friendly, more cost-effective alternatives."

VIDEO: (No sound) Animation of how Direct Laser Interference Patterning permits surfaces to be structured in ways that effectively repel ice.

The partners' next step will be to optimize the method and adapt it to various air zones. They will take into account the results obtained in real-world flight tests currently underway with an A350 aircraft whose surfaces have been treated with DLIP.

Source: Fraunhofer Institute for Material and Beam Technology IWS

Published April 2020

Rate this article

View our terms of use and privacy policy